Beretta 92FS Grips by Vu Kim Son

Kim Son Vu had a burgeoning business of making eyeglass frames, jewelry and accessories from natural materials. He was looking into expansion towards handgun grips. He had a problem though. In Vietnam, he is not allowed to own a firearm, not even a demilled frame of a gun to use as a guide.

Kim Son Vu had a burgeoning business of making eyeglass frames, jewelry and accessories from natural materials. He was looking into expansion towards handgun grips. He had a problem though. In Vietnam, he is not allowed to own a firearm, not even a demilled frame of a gun to use as a guide. As a result, Kim Son Vu hand crafts his grips without the benefit of a firearm to fit them to. Meticulously making a copy of a grip sent to him, he uses materials as varied as buffalo horn to abalone.

Kim Son uses the thick, compact tip of the buffalo horn for his grips. This results in a grip that is stable and does not shrink or warp. Once the grips are roughed in and drilled for screws, each screw hole receives a brass washer at it's base to prevent stress on the grip.

When questioned about the instability of horn grips, Kim Son responded

"You seen serious problem:To test this theory, unbeknownst to Kim Son, after I reviewed his Dust of Life horn grips, I removed them and hung them on the wall in my unheated garage, just to see if the changes in heat and humidity affected the grips. I forgot about them. They hung on finishing nails through the heat and humidity of two Louisiana Summers and the cold of a wet Winter and a half. I took them down to try on a pistol for this review. In the year and a half since I last reviewed Kim Son's horn grips, they are as stable as ever. Today, they drop on the pistol's bushings as easily as the day I received them.

Horn will shrinkage or deform at the part which you produce!They produce cheaper prices because they not use tip horn to do , the hollow part of horn will shrinkage or deform!Because they press it to big part and produce grips!

1. Your items buy form Philippines made from don't use tip.

2. My grips produce as correct every detail,special in two hole!It will not shrinkage or deform!"

1911 grips are relatively easy to manufacture. The sides are straight, and the curvature not too crucial.

The reverse side is flat. The design is forgiving. Beretta 92FS grips are another matter. The compound curves and angles of the Beretta grips are complex. With a trigger bar that moves underneath the grip and an enlarged hammer pin head that fits into a circular recess, the possibilities for ill fitting slabs of horn are increased exponentially.

The reverse side is flat. The design is forgiving. Beretta 92FS grips are another matter. The compound curves and angles of the Beretta grips are complex. With a trigger bar that moves underneath the grip and an enlarged hammer pin head that fits into a circular recess, the possibilities for ill fitting slabs of horn are increased exponentially. When Kim Son decided to manufacture Beretta grips, I started to caution against it. I should have known better. With an uncanny ability to manufacture grips to fit a pistol half a world away, Kim Son again sent me polished slabs of buffalo horn that dropped right onto the bushings of my pistol.

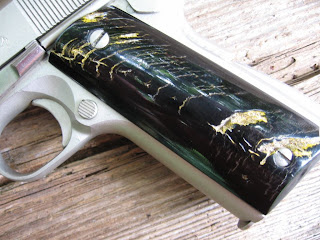

The Beretta grips I received were the black buffalo horn with "vein". Even before I screwed the grips down, they would not wiggle on the Beretta bushings.

The grips were beautiful.

The polish highly reflective, and the texture of the horn, the vein, showed through with a depth that is usually seen with layers and layers of lacquer. Yet there was no lacquer. The horn was simply, and expertly polished.

The polish highly reflective, and the texture of the horn, the vein, showed through with a depth that is usually seen with layers and layers of lacquer. Yet there was no lacquer. The horn was simply, and expertly polished. With the grips screwed snugly to the frame of the Beretta, everything functioned as it should. The trigger's draw bar did not bind, the slide reciprocated without impedance, the slide stop worked perfectly, and the magazine release had adequate clearance.

The width of the grips felt right. There seemed to be no extra material added to the Beretta grip frame's already corpulent girth. The magazine release could have benefited from a relief depression behind it, to allow the thumb to depress it easier. It was still manageable for me though.

I began to think how difficult it must be to build a grip for a pistol you have never held, let alone shot.

Under those circumstances, little things such as a magazine button depression can be overlooked.

Under those circumstances, little things such as a magazine button depression can be overlooked. On the right side of the pistol, the upper rear of the grip failed to cover the recess for the draw bar. There was approximately a 1mm area where dirt and grit could enter the mechanism of the gun. Realistically, debris could also enter the front, underneath the trigger bar, so the point is moot except for cosmetics.

Of course, cosmetics is everything for a pair of grips marketed and purchased for their beauty. I sent Kim Son an email and a photo of the area. I feel fairly certain that the needed material was removed in the polishing process. The polisher and the craftsman probably had no idea what the grips covered.

Now, here's the rub....... I don't like slickery handles on my hog legs. In fact, I eschew decorative grips, medallions and the entire presto change-o Barbie doll thing some people do with grips.

I tend to find a set of grips I like to shoot the weapon with, and they stay with the gun thereafter. Very few of them are smooth.

I tend to find a set of grips I like to shoot the weapon with, and they stay with the gun thereafter. Very few of them are smooth. I own a 1911 or two with smooth grips, stag or ivory; but my working guns wear checkered rubber. My concealed carry guns either wear checkered rubber or checkered hardwood. I want my front straps smooth and I count on my lateral squeeze to control the gun. Under fire, I did not like the way the Beretta performed with these grips. The chunky grip frame just did not feel secure in my hands. Out of curiosity, I measured the girth with the original grips attached. Five and three quarters inches at it's smallest point. With Kim Son's grips, in the same area, the gun measured 5 and 5/8 inches. His grips were actually less bulky! The difference had to be the lack of checkering on the buffalo horn grips. For me, that just did not work. It didn't feel right, and I will be putting the original grips back on my Beretta 92FS.

That really doesn't surprise me.

When my Beretta was new, I ordered a set of the genuine Beretta walnut grips for it. They were scarce back then, and I waited three or four months for them to arrive. I shot the pistol a few times with the smooth wood, and then sold them at the next gun show.

When my Beretta was new, I ordered a set of the genuine Beretta walnut grips for it. They were scarce back then, and I waited three or four months for them to arrive. I shot the pistol a few times with the smooth wood, and then sold them at the next gun show. If, however, you are the kind of shooter that likes smooth grips, and especially if you have an Inox Beretta 92FS, then these grips may be the chipotle in your taco. They are beautifully crafted, and will no doubt be as durable as the grips that weathered the temperature extremes in my garage for a year and a half.

Kim Son Vu also sent me some polished buffalo horn 1911 grips with a mother of pearl Maltese cross inset into each side.

The workmanship on these grips is exquisite. Watching the video below of the mother of pearl being cut and realizing that it is a inset chunk, not an overlay, the precision of his handiwork is amazing.

The workmanship on these grips is exquisite. Watching the video below of the mother of pearl being cut and realizing that it is a inset chunk, not an overlay, the precision of his handiwork is amazing. In the forum thread I linked above, you will find that Kim Son has received a couple of grips and then failed to manufacture the sender his replacements. In particular, one set for a S&W 39-2, and another set for a SIG P225/P6. I make no excuses for him, but I do realize that the more esoteric a grip is, the less the businessman stands to profit by making replacements. I hope that the originals are returned back to their owners soon, with lagniappe for their trouble.

* After The High Road became two forums, the thread concerning Kim Son's grips became two threads. Another version of the thread can be found here, at THR.us. Kim Son is participating and adressing issues in both threads.

Update It seems as if Kim Son has disappeared and has stiffed several people who helped him, never sending them the grips he promised. Caveat emptor.

Labels: Beretta, Vu Kim Son